Pulse-Jet Filter Bags

made of needle felt and glass fibre fabric

BWF Envirotec designs its Pulse-Jet filter bags to meet the individual requirements of the given dust removal process. That way customers are assured the best technical solution for their filter systems.

Custom built filter bags from BWF Envirotec

We supply filter bags for a wide range of filter systems and applications, together with the appropriate supporting cages. Filter media and surface finish are designed specifically to match your filtration process.

BWF Envirotec filter bags stand for unsurpassed filtration performance. They are characterised by very low emission values. Excellent mechanical, thermal and chemical resistances, as well as easy cleaning are further advantages.

Pulse-Jet filter bag - designs at glance

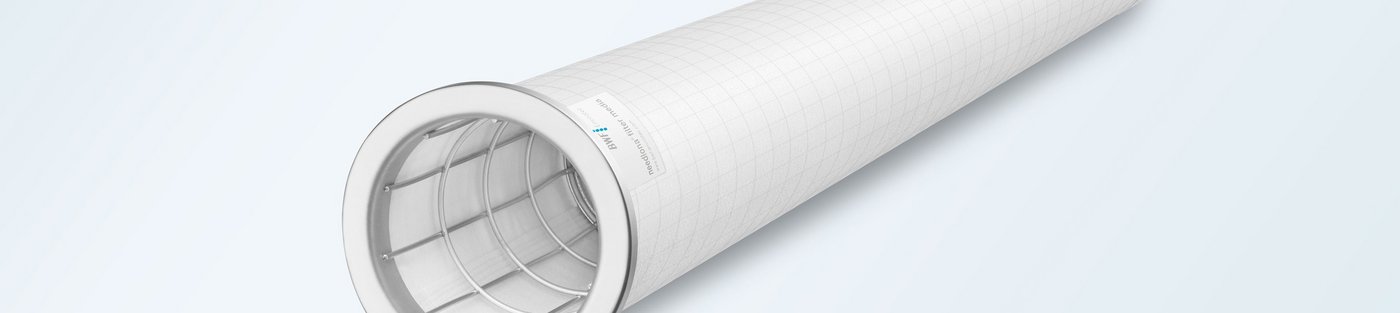

- Sturdy filter bag head: featuring snap ring, cord, ring or cut edge head design: separate or integrated top, head mounting piece with reinforcements and grounding wire

- Hose designed for improved stability, with stiffening rings for cageless constructions

- High quality seam designed for lowest emissions: Sewn, welded, with additional PTFE seam seal

- Floor construction for mechanical robustness and extended service life: With reinforced floor covering, double-layered bottom

Pulse-Jet filter bags for dedusting in the baghouse

The dust filters of a Jet-Pulse baghouse are used in baghouses consisting of one or more chambers. Each chamber contains several rows of pulse-jet filters, which are stabilized by means of a support basket and attached to a head plate. The particle-loaded gas flows through the pulse-jet filters from the outside to the inside, causing a filter cake to build up on the surface of the filter medium. As the thickness of the filter cake increases, it acts as a highly efficient filter. The build-up of the filter cake increases the pressure loss and therefore the energy requirement. For this reason, the filter is cleaned at certain intervals by a jet of compressed air directed against the air flow. The accumulated dust layer falls downwards and is discharged from the process through a funnel.

Pulse-Jet filter bags from BWF Envirotec - the filtration solution for a wide range of baghouses

Due to rising energy costs, there is a requirement to use the most energy-efficient pulse-jet filters possible for dedusting. The jet-pulse filters must also comply with increasingly stringent environmental regulations. With the use of state-of-the-art and highly effective dedusting technology from BWF Envirotec, you score multiple points: Thanks to our decades of experience and know-how in the field of industrial dedusting with pulse-jet filter bags, we determine the optimum filter medium and filter design for each individual baghouse. This enables us to minimize the pressure loss in the filtration process, improve the cleaning performance and at the same time increase the service life of the pulse-jet filters.

8 reasons to use BWF Envirotec Pulse-Jet filter bags

Put us to the test

Over 50 years' experience in industrial filtration and filter bag production.

2,100 Standard products and 17,000 worldwide applications available at the click of a mouse.

15 Production and sales locations and a global network of partners means that we always speak our customers' language.

Our industrial filters benefit from continual research and development: All finishes are applied in our R&D competence centre.

At BWF Envirotec, all products are manufactured in-house in a continuous process chain: Filter medium - filter bag - service - everything from a single source and company.

Whether it's assembly, commissioning, maintenance, repair or optimisation - we service filter bags for a wide range of reasons, but with only one goal in mind: Your total satisfaction.

Professional support beginning with the first consultation - our sales department and application technology stay by your side in word and deed throughout the entire process.

The BWF Envirotec Training Academy offers customers basic and practical seminars either on our premises, or directly on site.

FAQs on Pulse-Jet filter bags from BWF Envirotec:

A filter bag is filtration technology for filtering dust in a baghouse. It separates dust, harmful substances and also products from gas flows.

With over 50 years of experience, BWF Envirotec is the leading manufacturer of filter media and filter bags for dedusting processes in the processing industry.

Filter bags consist of needle felt or fabrics made of synthetic fibres. The needle felt is optimally adjusted for the application case at hand.

Filter bags are used for dust removal processes and for filtering waste gas and exhaust air in industrial plants. They make it possible to comply with the legal limits for (fine) dust emission and thus ensure clean air.

The internal support fabric gives the filter bag additional strength that makes both frequent bag cleaning and a long service life possible.