Raw materials for felt production

Selected and applied with care

BWF Feltec stands for the highest product quality, a commitment that begins with selecting and purchasing its raw materials. This commitment is further guaranteed by excellent quality management.

Our internal, twin quality management system ensures consistent quality while also taking environmental guidelines into account. As a supplementary, independent body, the ECO Umweltinstitut (Environmental Institute) regularly audits our quality standards.

BWF Feltec actively supports the CAMPAIGN FOR WOOL. Click the link for more information: www.campaignforwool.com.

Advantages of raw materials

- exclusively high-quality raw materials

- ISO certifications

- Öko-Tex certifications

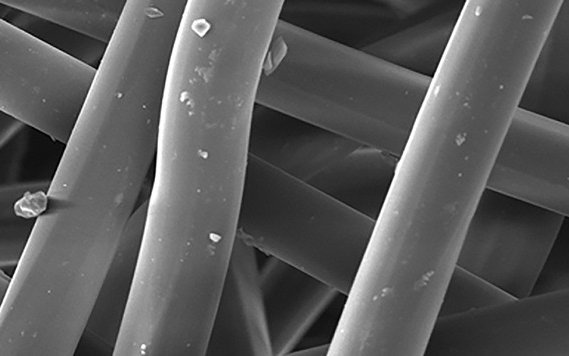

Wool

The natural raw material

xxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxx

The properties of wool

Downloads

Viscose

With fibres made of natural cellulose

Viscose is produced using a wet spinning process. The product is based on pulp, which is obtained from wood. The action of caustic soda lye and carbon disulphide produces a viscous, spinnable mass. The spinning mass is then pressed through nozzles. To remove the solvents, the spinning cable is led through a bath. After several de-aeration and separation processes, this strand is then dried, stretched and crimped. This improves strength and facilitates subsequent processing of the individual fibres. Finally, the strand is cut into short fibres.

The properties of viscose

Polyester

A synthetic raw material

Polyethylene terephthalate (PET) belongs to the polyester family. Terephthalic acid and ethylene glycol react to PET by polycondensation.

PET is produced by a melt spinning process: The molten polymer is pressed through spinnerets and an antistatic agent is introduced to prevent the individual strands from becoming electrostatically charged. In order to facilitate subsequent fibre processing, the final step after stretching is crimping and cutting.