Felt Rollers & Felt Belts for HTM Handling

High-temperature resistant felts for the aluminum and glass industry

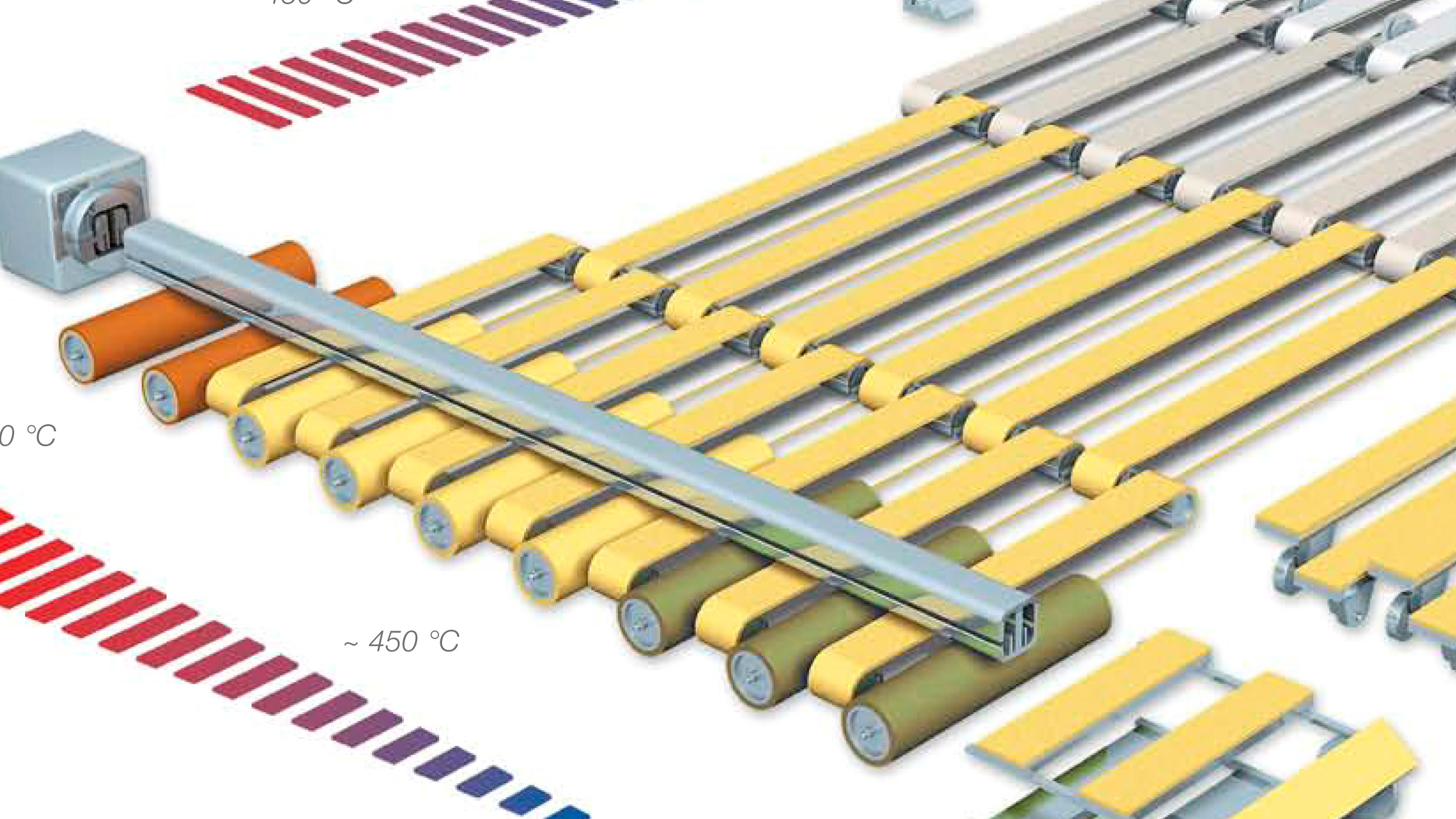

HTM Handling is our abbreviation for High-Temperature Material Handling, i.e. the handling and transportation of materials that are produced at high temperatures. In particular, endless needled felt rollers and belts are used in aluminum extrusion and in the glass industry.

Endless needled felt rollers and belts as well as needle felt pads transport sensitive aluminum profiles across the run-out tables of aluminum extrusion lines worldwide. Special felts and felt components made from special fibers are also used in the glass industry for high-temperature applications, such as in glass bending units.

BWF EXTRU-LINE® felt rollers, felt belts and more

for aluminum extrusion in action

Endless needled felt rollers and felt belts are used in the various temperature ranges on the run-out tables of aluminum extrusion presses. The freshly pressed aluminum profile arrives on the run-out table at around 500 - 550°C. A felt roller or felt belt (both endless round needled) at this point must therefore also have the appropriate temperature resistance, so PBO felt is generally used. Endless needled felt rollers and belts made of para-aramid, meta-aramid, polyester, always adapted to the respective temperature range, then follow in the further course of the cooling process.

We also offer our customers spacer materials made of needle felt for use in tempering furnaces.

Around the world, customers in the aluminum extrusion sector appreciate high-quality felt products from BWF Protec for their run-out tables. Both plant manufacturers, OEMs and direct customers from the aluminum industry purchase felt rollers, belts or other products such as spacer covers and felt pads.

We are pleased to supply the following companies, among others:

- Hydro Extrusion

- Constellium

- SMS

Do you have questions about your application?

Please contact us for individual solutions.

Your contact partner at BWF Protec

HTM Handling - FAQ

Questions and answers about endless needled rollers and belts

Endless needled felt rollers (not to be confused with felt yard goods in rolls) and endless, continuous felt belts (endless needled belts made of needle felt) are mainly purchased by customers in the aluminum extrusion industry who value the gentle transport of extruded aluminum profiles. Plant manufacturers purchase both rollers and belts made of felt (needle felt) for the initial assembly or replacement assembly, while end customers buy directly for replacement assembly.

Products made of felt or needle felt are particularly soft on the surface of aluminium profiles due to their textile nature. This is particularly important for products for visible surfaces. The materials are also very durable and are available in various designs for the entire temperature range during the cooling process.

Compared to woven belts, felt belts in particular have much lower elongation, i.e. they stretch much less.

The aforementioned properties also play a decisive role "in favour of felt" in the glass industry.

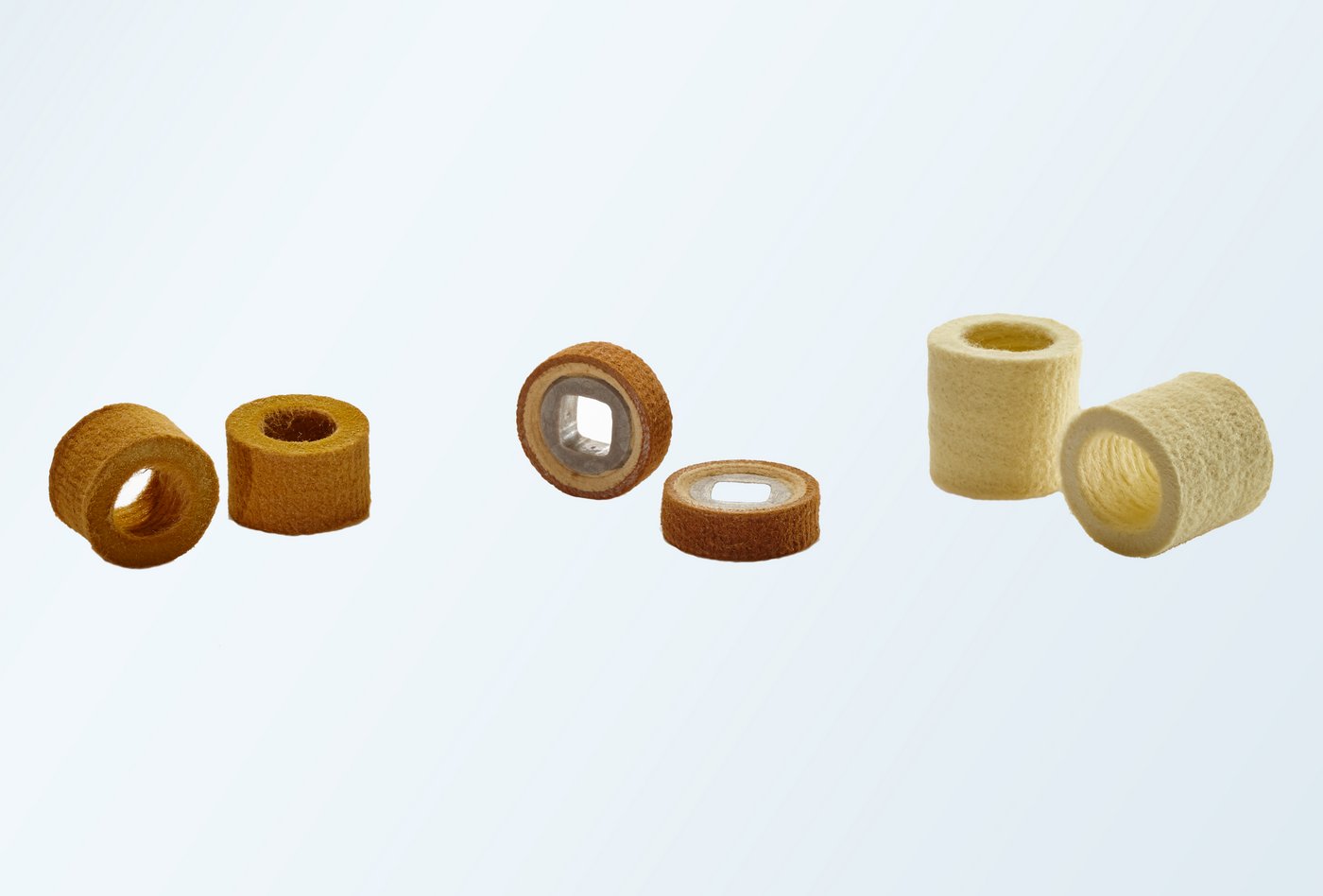

The temperature of an aluminium profile is around 550°C in the outlet area. This is also where the temperature range of an endless needled felt roller starts. PBO is the fibre of choice here. Then come felt products made of para-aramid (up to 500°C at the peak) or a mixture of para-aramid and pre-oxidised PAN (up to 450°C at the peak), followed by meta-aramid (240°C at the peak) and polyester (up to 150°C). The felt tube/felt roller can be constructed from different layers of needle felt, depending on requirements, needs and cost-effectiveness. The same naturally also applies to our endless needle felt belts.

Yes, felt tape is also available by the metre. In contrast to our endless belts, however, these are made from our needle felt by the metre. The "felt on a roll" is cut into narrow "slices" on our cutting machine or, technically limited to shorter strips, cut to size on our cutting table. Such strips are also used in the glass industry, for example.

![[Translate to English:] Aluminumprofilz auf Nadelfilzerollen](/fileadmin/_processed_/b/5/csm_bwf-protec-htm-handling-aluminium-glas_5b5ae60820.jpg)

![[Translate to English:] Technischer Nadelfilz: Meterware, Rohre, Bänder](/fileadmin/_processed_/a/f/csm_Collage_Produktbroschuere_73b4d9bcb8.jpg)