Filter Media for Industrial Filters

made of needle felt and fiberglass fabric

At BWF Envirotec you get over 2,100 different filter media in roll goods - the right filter medium for every dust and every industrial filter. As an industrial filter manufacturer, we specialize in filtering all types of dust including fine dust.

For bagmakers, we produce roll goods made from synthetic needle felt and fiberglass fabric. We process all common polymer fibers into the filter medium. We develop custom-made products individually for you upon request.

- BWF Envirotec filter media is made from synthetic fibers. In addition, a supporting scrim ensures stability.

- Every dust that arises during industrial production has different properties: fine, sticky, abrasive, chemically aggressive, hot or even explosive. That's why every dust requires its own filter medium designed for it.

Filter material -

production process at BWF Envirotec

Our high-tech machinery ensures that a highly effective filter material is created from fibers and fabric in many different work steps. The multi-layer fiber structure and a supporting scrim make the filter media extremely compact, dimensionally stable and mechanically resilient. Thermal processing processes are part of the production process. Filter media are z. B. simply singed, singed on both sides, calendered on one side or glazed on one side. Application-specific surface and protective finishes are applied in the final step. These are developed in our internal R&D competence center.

Filter media with surface and protective treatments achieve better cleaning performance and react less sensitively to mechanical wear and chemical influences. This greatly extends the service life of the filter materials. Depending on the area of application of the filter media, our treatments can be used individually or in combination.

Filter materials -

efficient in use against pollutants

Filter media offers high filtration efficiency and effectively filters particles of different sizes from the production process. By selecting the right filter media, you can achieve the desired filtration performance for your specific application. Filter media are robust and resistant to chemical influences and mechanical stress. They offer a long service life and can be used in demanding industrial environments without compromising their filtration performance.

Filter media as roll goods is available in various lengths, widths and designs, which offers a high level of flexibility in adapting to different bagmaking options. They can be easily cut and processed in various facilities for further processing. At BWF Envirotec you can get filter materials in a wide variety of packaging units.

Feel free to ask us! We will also find the optimal packaging unit and design for you.

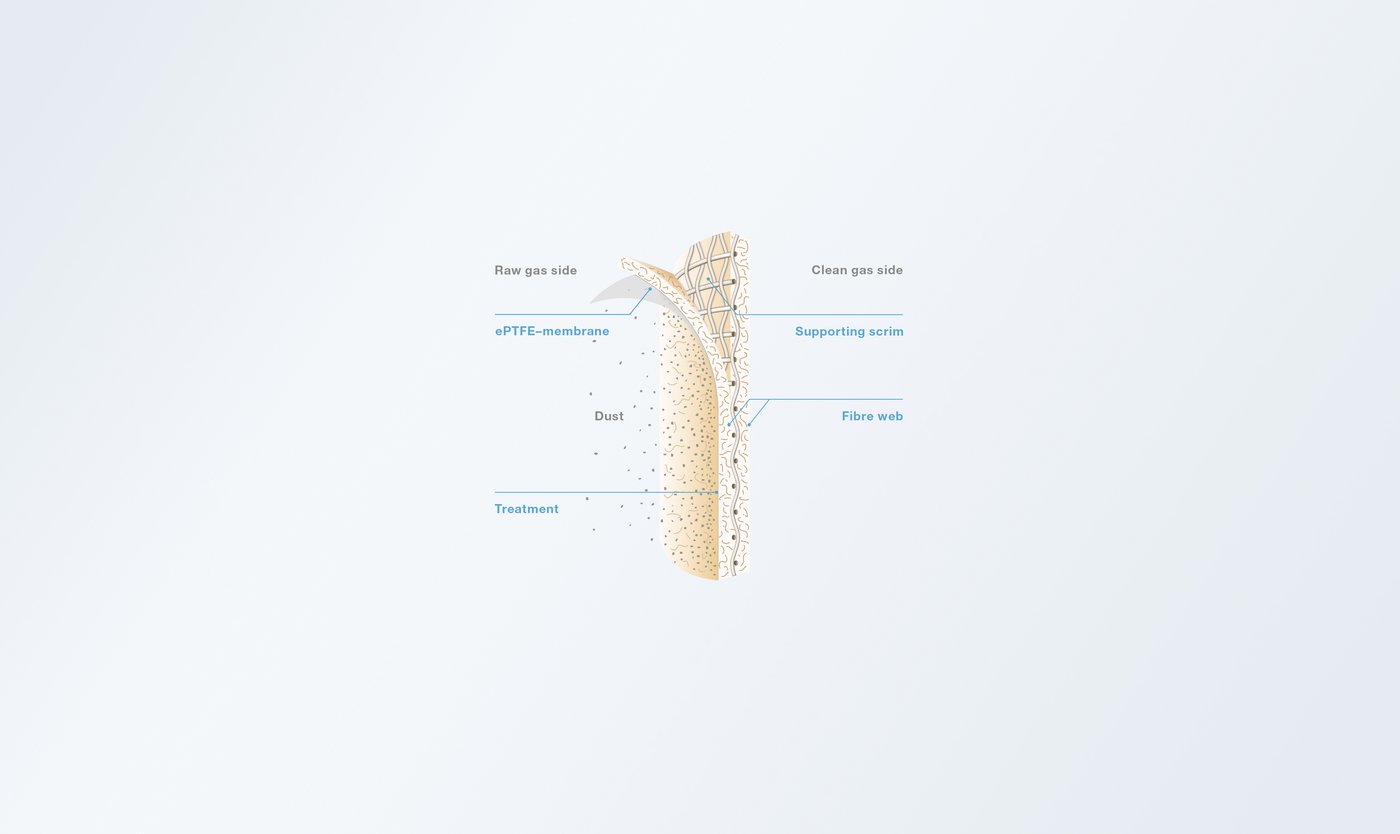

Filter media and their three-dimensional structure

Filter media are always three-dimensional structures. They consist of

- Fiber coating - on the raw gas side (with asymmetrical filler media there is no fiber coating on the raw gas side)

- Supporting scrim - ensures high tear resistance and reliable dimensional stability

- Fiber coating - on the clean gas side

- as well as, depending on the application, an e-PTFE membrane and/or chemical treatment

- The filter medium maintains its excellent dimensional stability through this multi-stage structure, which results in unique strength.

- The longer the filter bags become, the more dead weight and weight of the filter cake they have to carry and withstand. If a filter bag were to lengthen under the weight it has to carry, its service life would be significantly shortened.

- Dimensional stability through multi-dimensional structure of the filter media is therefore immensely important.

- Filter bags of up to 12 m and longer are often used in the filtration process. Longer filter bags create a smaller "geometric footprint", i.e. savings in material and manufacturing costs are taken into account when designing the filter system.

Industrial filter media - professional filter material from BWF Envirotec

Filter media as roll goods are indispensable components in industrial filtration. They offer high efficiency, longevity and cost-effectiveness.

- Synthetic needle felt with and without ePTFE membrane

- Glass fiber fabric with ePTFE membrane

- Working width up to 2.60 m

- Basis weight from 250 to 950 g/m²

- Design as roll goods or slitted roll material

- Core Product Catalog for filter media with shortest delivery time

- Special designs and development on customer request

Filter materials made of synthetic fibers and their use in filtering different dusts

- for use in the low temperature range and high temperature range

- for an efficient and reliable filtration solution in a variety of industries.

Filtration fibres and their interaction with different types of dust

Scrim and fibre types | Contin. Temperature* (Peak) Contin. Temperature* (Peak) | BWF Envirotec Designation BWF Envirotec Designation | Hydrolysis-Resistance Hydrolysis-Resistance | Acid-Resistance Acid-Resistance | Alkali-Resistance Alkali-Resistance | Oxidation-Resistance Oxidation-Resistance |

Polypropylene | Contin. Temperature* (Peak) 95 °C/(95 °C) | BWF Envirotec Designation PP | Hydrolysis-Resistance excellent | Acid-Resistance excellent | Alkali-Resistance excellent | Oxidation-Resistance limited |

Polyamide | Contin. Temperature* (Peak) 110 °C/(115 °C) | BWF Envirotec Designation PA | Hydrolysis-Resistance limited | Acid-Resistance limited | Alkali-Resistance good | Oxidation-Resistance limited |

Polyacrylnitrile copolymer | Contin. Temperature* (Peak) 115 °C/(120 °C) | BWF Envirotec Designation AC | Hydrolysis-Resistance limited | Acid-Resistance limited | Alkali-Resistance good | Oxidation-Resistance good |

Temperatur-resistant olefin | Contin. Temperature* (Peak) 125 °C/(135 °C) | BWF Envirotec Designation RO | Hydrolysis-Resistance excellent | Acid-Resistance excellent | Alkali-Resistance excellent | Oxidation-Resistance limited |

Polyacrylonitrile homopolymer | Contin. Temperature* (Peak) 125 °C/(140 °C) | BWF Envirotec Designation DT | Hydrolysis-Resistance good | Acid-Resistance good | Alkali-Resistance good | Oxidation-Resistance good |

Polyester | Contin. Temperature* (Peak) 150 °C/(150 °C) | BWF Envirotec Designation PE | Hydrolysis-Resistance limited | Acid-Resistance good | Alkali-Resistance limited | Oxidation-Resistance good |

Polyphenylene sulphide | Contin. Temperature* (Peak) 190 °C/(200 °C) | BWF Envirotec Designation PPS | Hydrolysis-Resistance excellent | Acid-Resistance excellent | Alkali-Resistance excellent | Oxidation-Resistance limited |

m-Aramide | Contin. Temperature* (Peak) 200 °C/(220 °C) | BWF Envirotec Designation NO, NX | Hydrolysis-Resistance limited | Acid-Resistance limited | Alkali-Resistance limited | Oxidation-Resistance good |

Polyimide | Contin. Temperature* (Peak) 240 °C/(260 °C) | BWF Envirotec Designation PI | Hydrolysis-Resistance good | Acid-Resistance limited | Alkali-Resistance limited | Oxidation-Resistance good |

Polytetrafluorethylene | Contin. Temperature* (Peak) 250 °C/(280 °C) | BWF Envirotec Designation PTFE, TFL | Hydrolysis-Resistance excellent | Acid-Resistance excellent | Alkali-Resistance excellent | Oxidation-Resistance excellent |

Fibreglass fabric | Contin. Temperature* (Peak) 260 °C/(288 °C) | BWF Envirotec Designation GL | Hydrolysis-Resistance good | Acid-Resistance limited | Alkali-Resistance limited | Oxidation-Resistance excellent |