Product Lines

The right filter for every conceivable dedusting application

Reliably reducing emissions and ensuring compliance with dust emission limits are two key tasks in dedusting. Our high-performance filters meet the most exacting requirements when it comes to dedusting exhaust air and flue gas.

Your benefits at a glance

- Meet strict emission limits

- High separation efficiency

- Low residual dust emission

- High abrasion resistance

- Good chemical resistance

- Filter even the finest dust particles

- Easy cleaning

Low pressure loss

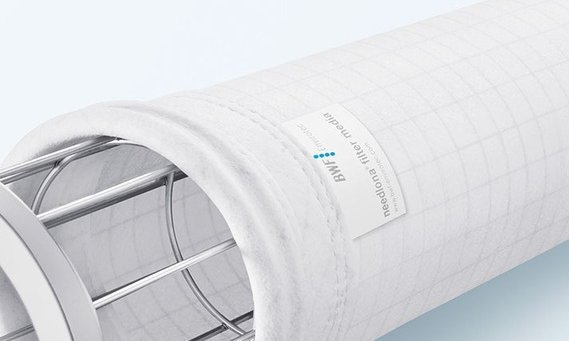

needlona® filter bags produced of needle felt

of all types of conventional polymer fibres

The fibre coating of needlona® filter bags is applied to a strong supporting scrim, this makes the filter extremely compact, dimensional stable and mechanically resistant for long service lives under the toughest conditions. Depending on the flue gas cleaning method, the high-efficency filters media are enhanced with various finishes.

Advantages of needlona® at a glance

- Fabric and scrim compatibility like: PP/RO – Polypropylene/Temperature Resistant Olefin, PA – Polyamide, DT – Polyacrylonitrile Homopolymer, PE – Polyester, NO/NX – m-Aramid, PPS – Polyphenylene Sulfide, PI – Polyimide, PTFE – Polytetrafluorethylen

- Improved eliminiation of the filter cake

- Constant differential pressure

- Constant gas flow rate

- Long service life and high productivity

Application

needlona® filter bags from BWF Envirotec are used in many areas, such as the cement, waste, wood, chemical, pharmaceutical, food, metal and plastics industries or in power stations.

needlona® BLUE - filter medium for a reduced CO₂ footprint

needlona® BLUE product line is the environmentally friendly filter medium with which we already achieve more than 10% CO2 savings in the manufacturing process compared to a standard filter medium. This is how we put our climate protection measures into practice. For a clean environment of the future.

needlona® BLUE is environmentally friendly and energy efficient thanks to

- increased use of high quality, recycled fibres

- own in-house recycling

- optimised use of operating resources in the production process

- reduced energy consumption in needle felt manufacturing

Calculation by ClimatePartner

The Product Carbon Footprint calculation is based on the GHG (Greenhouse Gas) Protocol. It records the CO2 emissions of needlona® BLUE in the individual phases of the product life cycle. This takes raw materials, manufacturing, transport and waste disposal into consideration.

PM-Tec® filter bags with ePTFE membrane

Fine dust doesn't stand a chance!

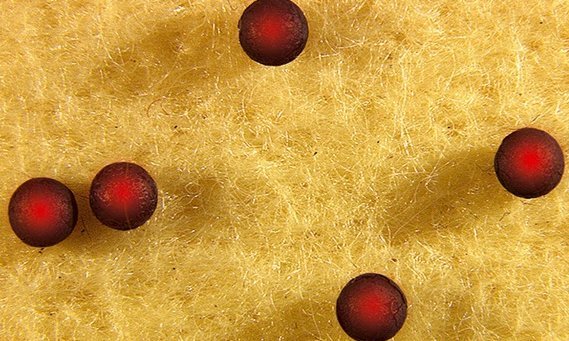

Particularly in industrial areas, fine dust can pose serious health risks, placing an enormous burden on both people and the environment. Lamination with a highly effective ePTFE membrane significantly increases filter media efficiency. Fine dust, measuring even in the submicron range, is thus already separated at the surface. Can be applied to needlona® needle felt and glass fibre fabric.

Advantages of PM-Tec® at a glance

Even the finest dust particles are separated beginning at the surface

Lowest emission levels, with zero emission a near possibility

No dust penetration into the carrier material

Excellent cleaning properties due to smooth, anti-adhesive surface

Constant differential pressure

Constant gas flow rate

Long service life and high productivity

Application

PM-Tec® filter bags from BWF Envirotec are used in many areas, such as the cement, waste, chemical, pharmaceutical, food, metal and plastics industries or in power stations.

ExCharge® to counteract explosive dusts

filter bags from BWF Envirotec

Safety is our top priority. This is why BWF Envirotec pioneered then launched the first filter medium tested by DEKRA GmbH. ExCharge® filter bags are manufactured from antistatic needlona® filter media. Its resistance value is significantly less than 106 Ohm (measured according to DIN 54345 Parts 1 and 5). High-quality stainless steel fibres in the supporting fabric ensure the filter bags' safe discharge.

ExCharge® is available for polypropylene, polyacrylonitrile, polyester, m-aramide, polyimide, polyphenylene sulfide and polytetrafluoroethylene needle felts.

Advantages of ExCharge® at a glance

Protects against explosions by permanently discharging electrostatic charge

Permanently antistatic behaviour due to high-quality stainless steel fibres in the carrier fabric

Application

ExCharge® filter bags from BWF Envirotec are used in the food, wood and chemical industries, for example, as well as in coal processing.

FoodTec® for the food industry

filter bags from BWF Envirotec

Producing foodstuffs entails strict hygiene rules. To ensure product purity, any filter bags used must be food safe. Our FoodTec®product line has been specially developed for applications in the food industry, and tested and certified by an independent institute.

Our test results lie far below legally permitted limits, confirming the outstanding properties and food safety of FoodTec® filter media. Compliance declarations are available for all PTFE, polyester and polypropylene FoodTec® needle felts. FoodTec® filter bags reliably separate all particles, ensuring that the product remains pure throughout the production process.

Advantages of FoodTec® at a glance

- Food safe

- Certified needle felt with compliance declaration according to Regulation (EU) No. 10/2011

- Manufacturing occurs according to GMP EC 2023/2006

- Available as ExCharge®

Application

FoodTec® filter bags from BWF Envirotec, for use in the food industry.

PZ filter media for workplace dedusting

filter bags from BWF Envirotec

In terms of employee health, one can't take shortcuts when it comes to dedusting the workplace. By using needlona® filter media with a test certificate (PZ), the workplace itself can become a clean environment.

PZ test certificates according to IEC 60335-2-69:2021-04, appendix AA are available for selected polyester needle felts.

Advantages of our "PZ" product line at a glance

- Tested and certified by an accredited institute for use in workplace dedusting.

Specified for dust classes "L" and "M".

Application

PZ filter bags from BWF Envirotec are used wherever cleaned air is pumped back into the workplace environment, as well as in dust-removing machines and equipment such as dust extractors in the woodworking industry, industrial vacuum cleaners and mechanical sweepers.

Dust classes

Dust category IEC 60335-2-69:2021-04, appendix AA | Application Application | Maximum admissible emission rate Maximum admissible emission rate |

L | Application dust separation with AGW values > 1 mg/m3 | Maximum admissible emission rate 1,0 % |

M | Application dust separation with AGW values ≥ 1 mg/m3 | Maximum admissible emission rate 0,1 % |

MPS® for fine dust separation

filter bags from BWF Envirotec

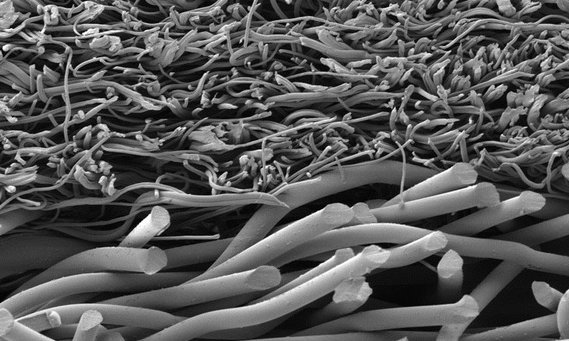

In MPS® filter media microfibres significantly increase the filter area of the needle felt, resulting in the greatest possible fibre surface. This means even the finest dusts are effectively separated.

Advantages of MPS® at a glance

Highest separation efficiency due to a surface oriented filtration

Lowest emission values

Reduced cleaning intervals mean extended service life

Favourable operating costs due to reduced consumption of energy and compressed air

Application

MPS® filter bags from BWF Envirotec are used e.g. in the cement and waste industry, as well as in power plants.

AsphalTec® for the asphalt industry

Filter Bags from BWF Envirotec

Both reverse air and jet pulse filter systems are used in asphalt mixing plants. BWF Envirotec's AsphalTec® filter media features a basis weight that is ideal for each of these systems. You can choose from weight classes beginning at 400 g/m² for reverse air and up to 550 g/m² for jet pulse filter systems.

Advantages of AsphalTec® at a glance

- Lowest emission values and long service life

Supporting fabric, homogeneous fibre layer and heat setting all ensure mechanical stability and resistance in the asphalt mixing plant

Application

AsphalTec® filter bags from BWF Envirotec are used in asphalt production.

BWF Envirotec filter bags with additional protective treatment

for optimal filtration results

All needlona® needle felts can be finished with a surface finish or protective treatment. This significantly improves service life, cleaning behaviour, dust cake formation and mechanical and chemical resistance. Protective treatment can be applied to all our product lines, in any number of ways.

Advantages of protective treatment at a glance

Optimum surface filtration

Lower energy costs due to the needle felt's efficient cleaning properties

Improved protection against mechanical and chemical influences

Increased economic efficiency due to extended service life

Si/Code9/x-surf finishes for abrasive dusts

filter bags from BWF Envirotec

Abrasive dust can do mechanical damage to the filter bag, shortening overall service life.

Fibre impregnations with silicone oil give needlona® needle felt anti-adhesive properties. These properties reduce fibre wear from abrasive dusts many times over.

All needlona® needle felts can be given an anti-adhesive finish. Depending upon the type and characteristics of the dust, we recommend Code9, Si or x-surf single fibre impregnation.

Advantages of Si/Code9/x-surf at a glance

Reduces fibre wear

Facilitates cake release

Application

BWF Envirotec filter bags with finishes for abrasive dusts are used, for example, in the lime, gypsum and cement industries.

CS18® plus and Glaze finishes for agglomerating dusts

filter bags from BWF Envirotec

Agglomerating dusts can be found, among others, in combustion or drying processes.

CS18® plus: A highly effective, concentrated application of PTFE polymers to the needle felt surface gives it excellent cleaning properties. This anti-adhesive surface coating reduces the adhesive forces acting between the filter medium and the dust cake, improving cleaning properties and creating low Δp behaviour in the filter system.

Especially with agglomerating dusts, additional calendering and/or a smoothed surface makes for excellent dust cleaning characteristics. Glaze thus leads to reduced pressure loss.

Your benefits at a glance

CS18® plus:

- Microporous and anti-adhesive

- Causes low Δp behaviour

- Extends the service life of the filter medium

Glaze:

- Improved cleaning properties

- Reduced pressure loss

Application

BWF Envirotec filter bags with finishes for agglomerating dusts are used in the chemical and pharmaceutical industries, in the cement, lime and gypsum industries, in the food industry, in waste incineration plants and in biomass thermal power stations. Needle felt treated with glaze is also suitable for use in CIP systems.

FireGuard and BlockGuard finishes to counteract flying sparks

filter bags from BWF Envirotec

Especially during metallurgical processes hot, partially glowing particles may come into contact with the filter bag. Our FireGuard and BlockGuard product series protect against these forms of dust.

FireGuard is a high-tech p-aramid surface finish that increases resistance to flying sparks. FireGuard also offers excellent resistance to abrasion and mechanical wear.

BlockGuard consists of a layer of spark resistant Preox fibres. It is mainly used on polyester needle felt, and presents a solution for occasional sparks that may occur in the raw gas flow of the filter system.

Your benefits at a glance

FireGuard:

Excellent protection against flying sparks

Thermally resistant even at high contact temperatures

Extended service life

BlockGuard:

Basic protection for occasional flying sparks

Very good price/performance ratio

Excellent pressure loss

Application

BWF Envirotec filter bags with finishes that protect against flying sparks are used, for example, in the metalworking or the non-ferrous metal industries.

CS29® and CS52 finishes against acid and alkaline dusts

filter bags from BWF Envirotec

Needle felts can also be processed with a surface finish from our CS product line that protects against acidic and alkaline dusts.

Oil- and water-repellent impregnation provides additional protection against acids. CS29® is a finish that provides excellent protection for the needle felt against acids, alkalis and hydrolysis. What's more, CS29® features outstanding oil and water repellency.

CS52 is a protective finish against acid, alkali and hydrolysis for m-aramid filter media that repels oil and water. An additional PTFE-based anti-adhesive finish improves dust separation properties.

Your benefits at a glance

CS29®:

Oil and water repellent

Excellent protection against acids, alkalis and hydrolysis

CS52:

Excellent protection against acids and alkalis

Improved protection against hydrolysis

Higher separation efficiencies

Application

BWF Envirotec filter bags with finishes to protect against acidic and alkaline dusts are used, for example, in the gypsum, lime, clay and cement industries.

CS17® and CS30 finishes for moist, oily and sticky dusts

filter bags from BWF Envirotec

CS17® is an oil- and water-repellent fibre impregnation that is based on fluorocarbon resin. It reduces the level of moisture that penetrates the needle felt, thus reducing the risk of excessive dust deposits and caking.

CS30PTFE fibre impregnation is used to filter fine, well-adhering dusts. Its PTFE properties make it both extremely durable and chemically resistant. CS31 is a combination of CS30 with a CS17® finish. It is also water- and oil-repellent. It also protects the needle felt from moisture and condensation.

Your benefits at a glance

CS17®:

- Oil and water repellent

- Improved cleaning

- Greater safety in discontinuous processes

CS30:

- Chemical protection

- Higher separation efficiencies

- Lowest emission values

Application

BWF Envirotec filter bags with finishes for moist, oily and sticky dusts are used e.g. in the lime, gypsum and cement industries, non-ferrous metal and steel production as well as in thermal waste treatment.