High-quality technical plastic profiles

Crucial for the optimal functionality of your products

Technical plastic extrusions are often invisible, yet indispensable functional components used in a wide range of industries and applications. They serve not only to improve the functionality of products, but also to meet specific technical requirements. Together with you, we develop customised solutions for your individual needs from the initial idea to the finished technical profile.

Technical plastic profiles: customised and functional

Your benefits at a glance

Many years of expertise in the development and production of customised plastic profiles

Greatest flexibility as a full-service provider for ‘lighting’ and ‘technical’ plastic profiles

High production standards through the use of modern manufacturing processes

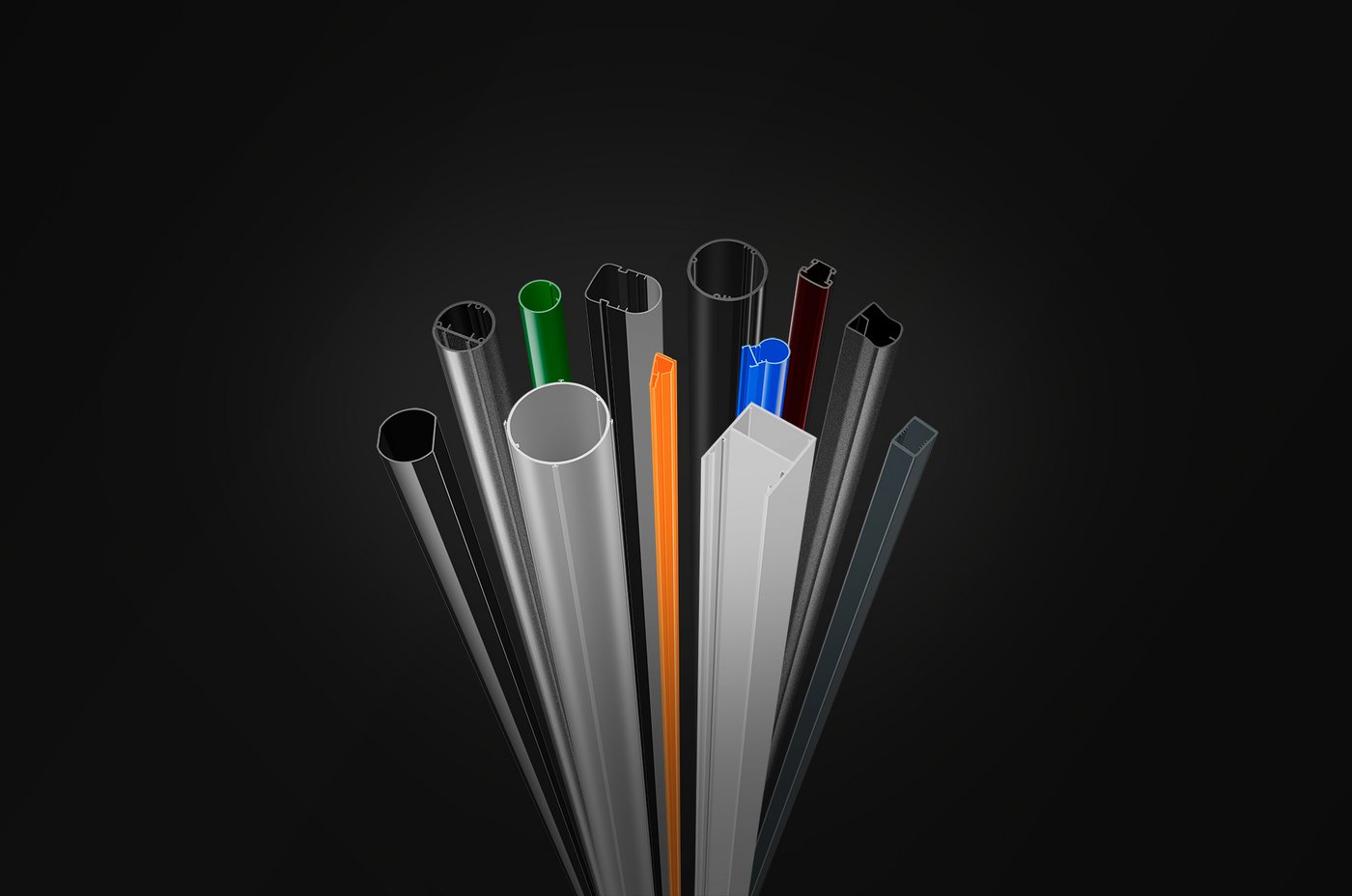

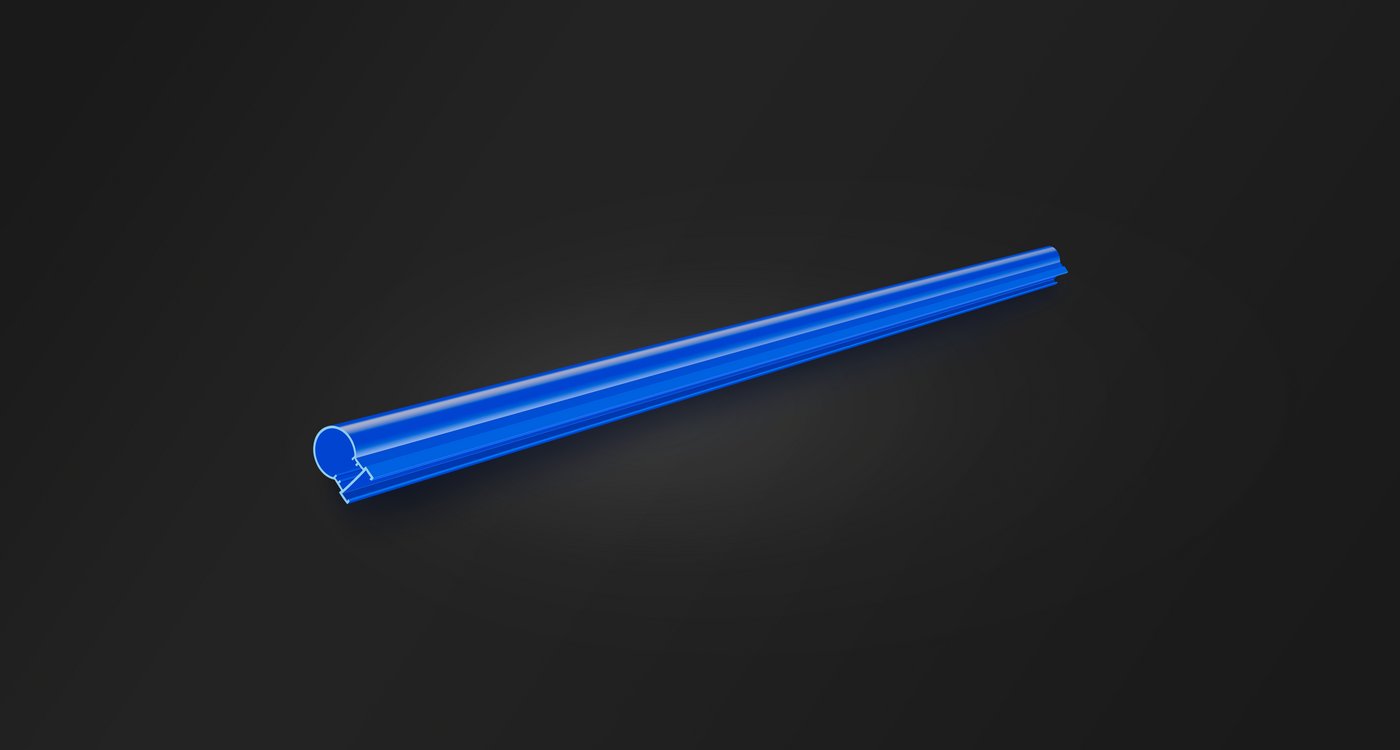

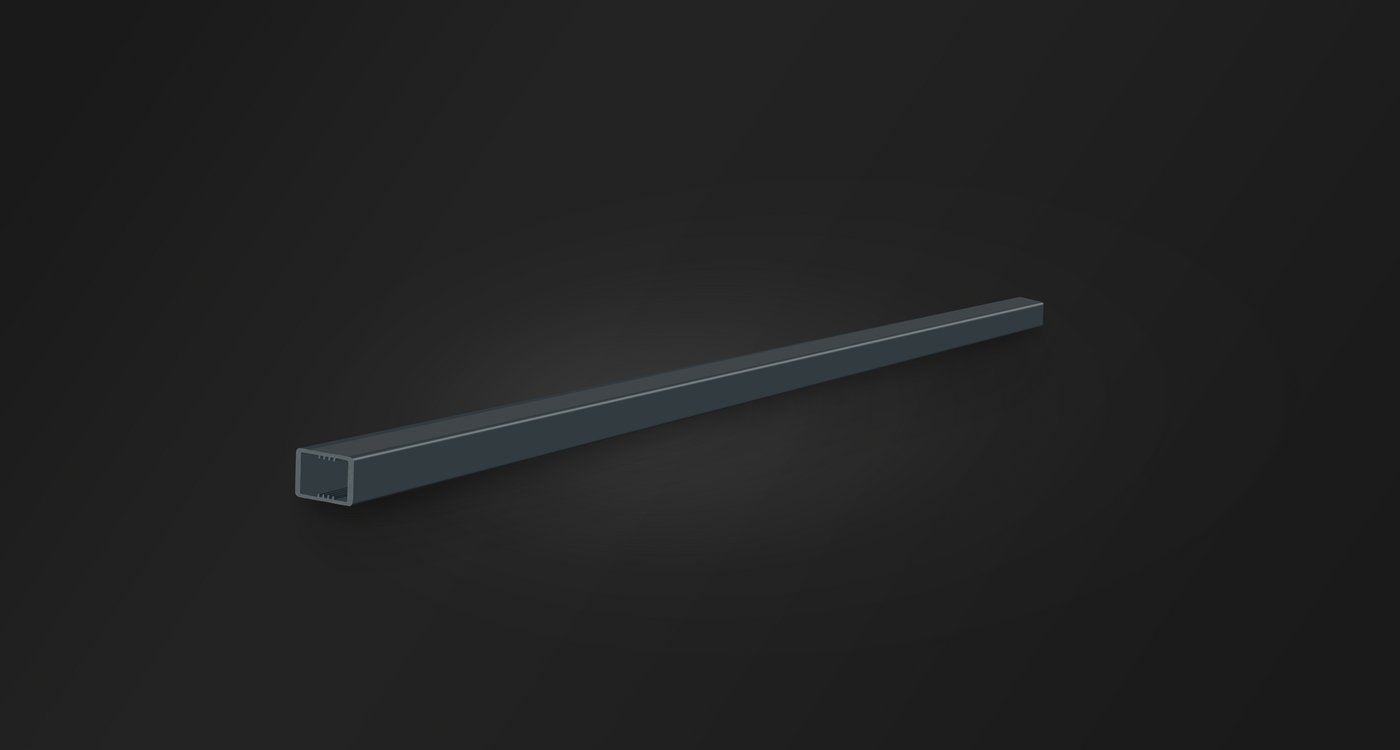

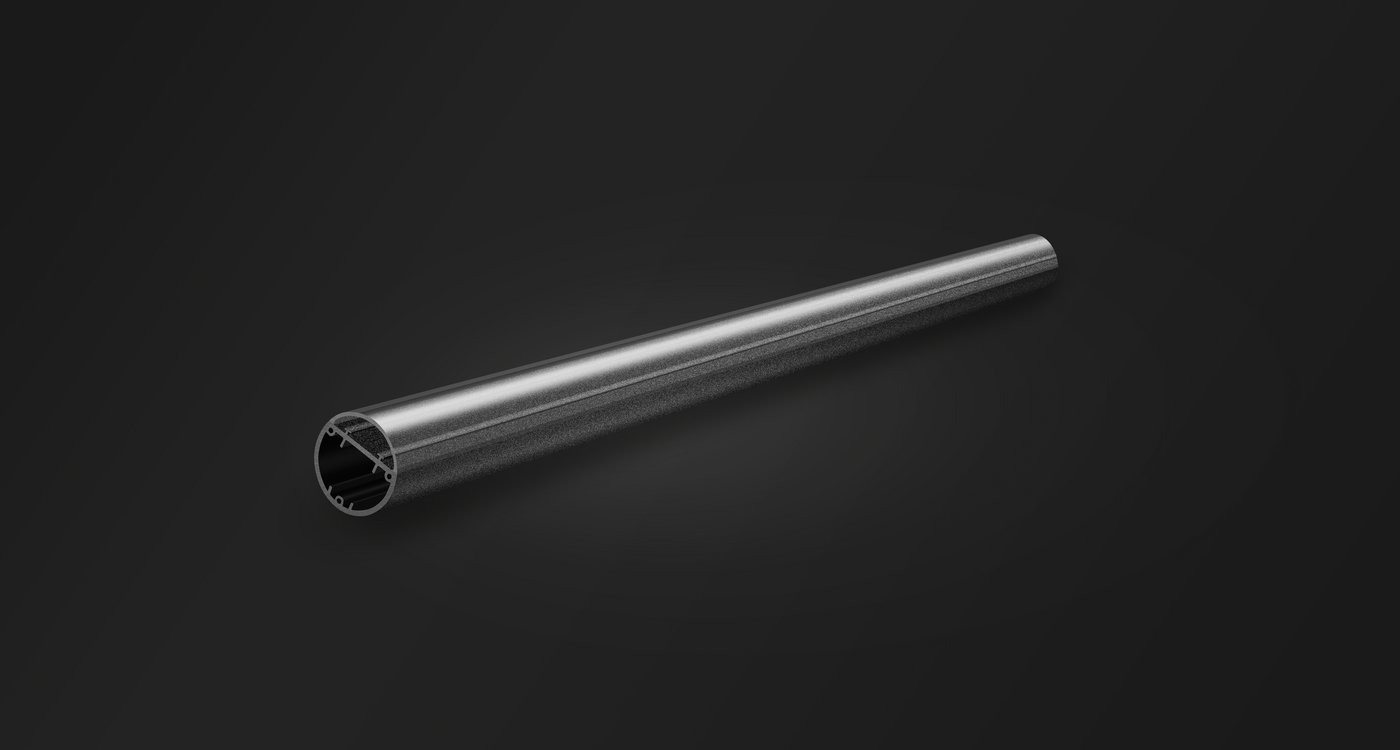

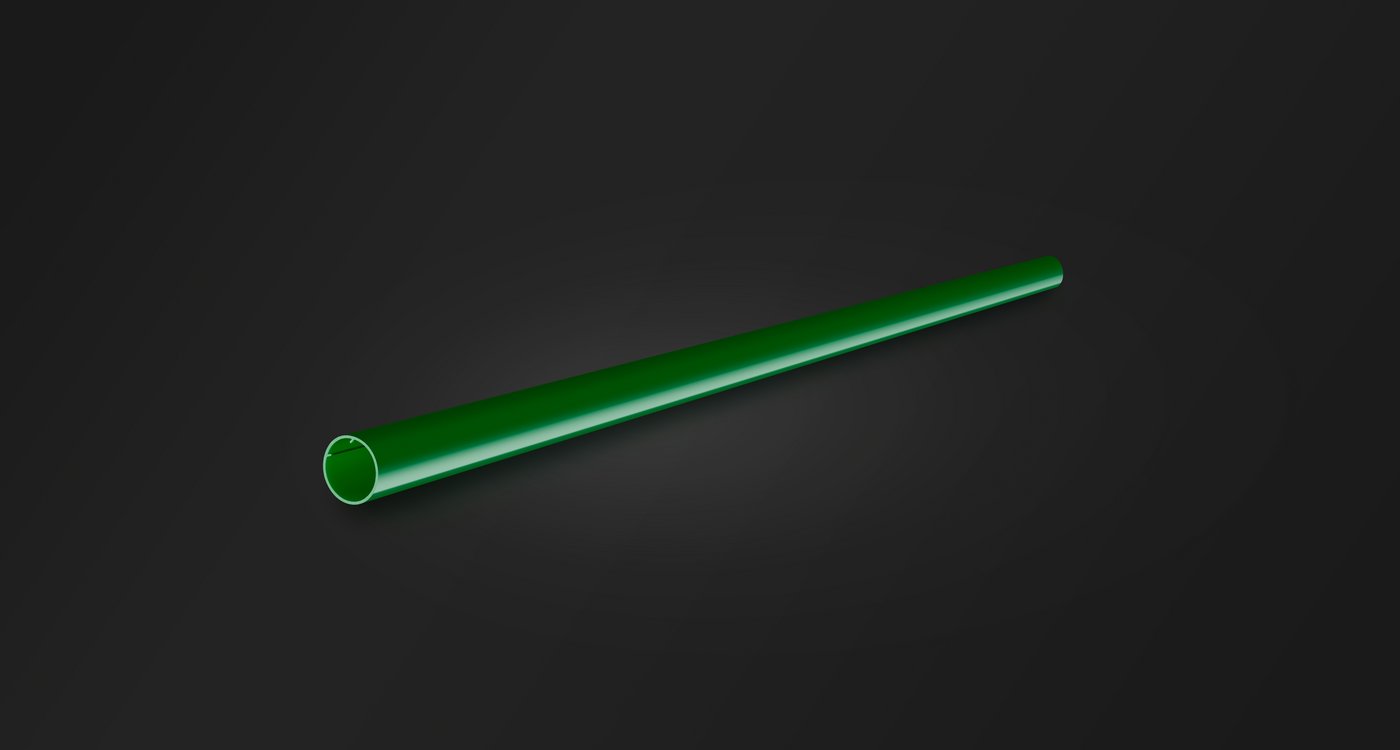

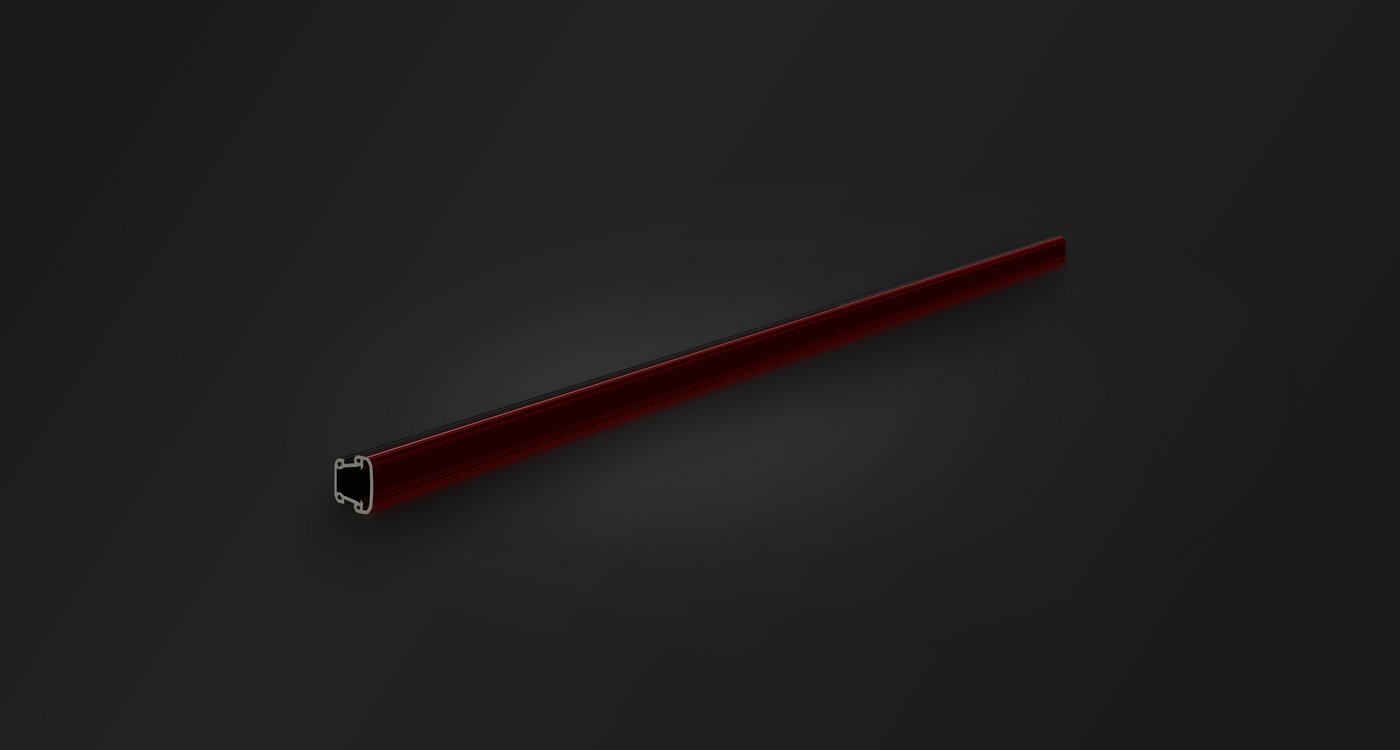

Product diversity: Whether closed, open or as a shaped tube – we offer plastic profiles for a wide range of technical requirements

Function-integrated components: Plastic profiles with integrated seals and other functional elements are possible

- Perfectly fitting product solutions thanks to our in-house colour laboratory, our own toolmaking and our service-oriented processing centre

- Diverse and customised material and colour selection

Put your trust in our experience and innovative strength to find the optimal solution for your specific product requirements.

Technical plastic profiles for a wide range of industries

Individually developed for your specific requirements

Technical plastic profiles for protection

- Impact protection: Versatile protective profiles for shock absorption and hazard marking, e.g. in production and storage halls, car parks and garages

- Construction machinery protection: Special profiles that act as ‘tooth protection’

- Tread plates: Minimisation of the risk of slipping, e.g. on industrial ladders

Materials for technical plastic profiles

First-class raw materials perfectly tailored to your application

The decisive factor for the quality of our plastic profiles is the targeted selection of the material depending on the product requirements, such as the long-term service temperature. To offer products with high functionality and exceptional durability, we rely exclusively on first-class raw materials. This is complemented by continuous and comprehensive quality testing in our laboratory. This is how we ensure that the quality of the raw materials and profiles remains consistently at the highest level.

- HDPE (high-density polyethylene)

- PA6 (polyamide 6)

- PA12 (polyamide 12)

- TPE (thermoplastic elastomers)

- ABS (acrylonitrile butadiene styrene)

- ASA (acrylonitrile styrene acrylate copolymer)

- PE (polyethylene)

- TPU (thermoplastic polyurethane

- PP (polypropylene)

- PP reinforced with talcum

Fibre glass reinforcement possible for various materials: the special fibre reinforcement provides additional mechanical strength.

What are the requirements of your product idea?

Please feel free to contact us and we will work closely with you throughout the entire development process, from the initial concept to toolmaking and prototype production, right up to the ready-to-install, production-ready plastic product. Cost-effective, fast and tailored to your needs.

Your direct line to our expert

for technical plastic products

BWF Kunststoffe GmbH & Co. KG

Bahnhofstraße 20